SiC Wafer Manufacturer Production Analysis

As one of the main representatives of the third generation of semiconductors, HMT provide 2 inch 4 inch 6 inch 8 inch SiC Wafers, As-cut SiC Wafer and SiC Boules to worldwide customers. SiC material has a wider band gap, higher breakdown electric field and higher thermal conductivity than silicon, and it performs well in the fields of high temperature, high pressure and high frequency.

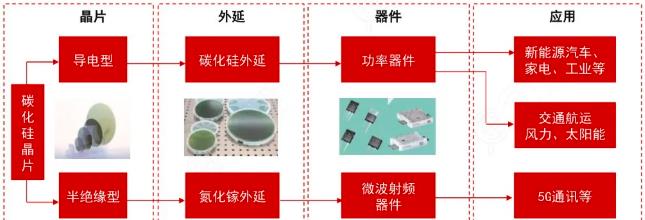

The SiC industry chain mainly includes equipment, substrate, epitaxy, design, devices and packaging modules.

SiC material comprehensive performance, can produce SiC bulletproof ceramics, mechanical seals, bearing bushing, heat exchange tube, micro-channel reactor, kiln kiln, etc., after carbon-carbon composite, material performance enhancement can be used in aerospace, military nuclear energy and other industries, is an important semiconductor material for smart grid, new energy vehicles, 5G applications and other emerging industries.

In the field of new energy vehicles: mainly used in PCU (power control unit) and OBC (charging unit), compared with silicon devices, SiC devices can reduce the weight and volume of PCU devices, reduce switching losses, and improve the operating temperature and system efficiency of the devices; Improve the power level of OBC unit, simplify the circuit structure, improve the power density, and improve the charging speed.

Photovoltaic power generation field: SiC material has lower on-resistance, gate charge and reverse recovery charge characteristics, the use of SiC device photovoltaic inverter, the conversion efficiency can be increased from 96% to 99%+, energy loss reduced by 50%+, equipment cycle life increased by 50 times.

CATEGORIES

LATEST NEWS

- Introduction to the main functions of PbootCMS

Further Application of SiC Power Devices In New Energy Vehicles

- Introduction to the main functions of PbootCMS

SiC Wafer Manufacturer Production Analysis

- Introduction to the main functions of PbootCMS

Silicon Carbide SiC Wafer Polishing New Direction

- Introduction to the main functions of PbootCMS

SiC Boules and SiC Substrates industry chain

CONTACT US

Contact: Mr.Kimrui

Phone: 15366208370

Tel: 15366208370

Email: kim@homray-material.com

Add: LiSheng Industrial Building, 60SuLi Road, WuZhong District, JiangSu Province, P.R.China.